NEW LAUNCH : Dynamic Image Analysis at the Touch of a Button

BDH Marketing 371 views

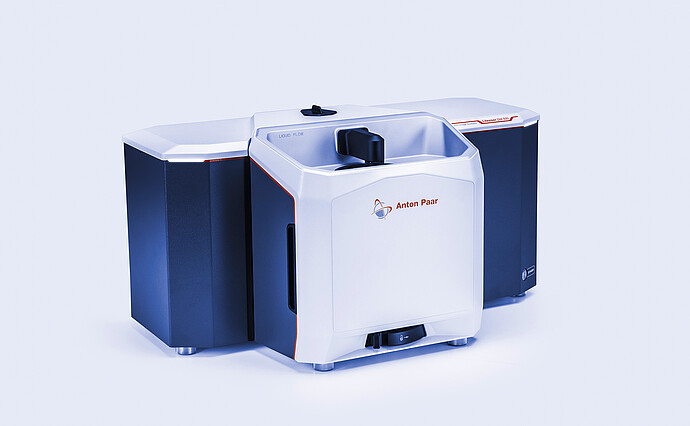

Dynamic Image Analysis at the Touch of a Button

Litesizer DIA 500 is the latest instrument in the Particle Analysis & Surface Charge (PC) product line portfolio. The instrument measures the size and shape of particles from 0.8 µm to 8,000 µm (1 µm = 0.001 millimeter), joining the PSA and Litesizer DLS series.

Dynamic Image Analysis as a direct measurement method

Litesizer DIA 500 is based on the Dynamic Image Analysis method which provides a unique opportunity of performing a direct measurement using a high-resolution, high-speed camera. With the dynamic image analysis, users rely on direct information rather than on interpretation of a physical phenomenon. The instrument captures up to hundreds of thousands of images of the particles per second, which are then automatically analyzed. With the DIA method, you can have a look at each and every detected particle separately. In simple words: what you see is what you get!

Operating in various industries

Litesizer DIA offers a new solution in various application areas – the food industry is among the largest, low-hanging fruits since most of particles in this sector are irregular and their shape play a great role in processing. But there is much more out there: for example, in the battery industry for measuring the size and shape of raw materials used in electrode production to achieve higher energy density and battery performance. The Litesizer DIA can also be used to examine the shape and size of metal powders used in laser sintering (3D printing). Another application option is the examination of abrasives for the optimal deburring of workpieces.

Advantages over the competition

Anton Paar’s KalliopeTM software, developed for particle analysis, provides all sample information at a click and can quickly visualize the data, being filtered and recalculated according to the user’s wishes. Features such as automatic filling, emptying and rinsing of the dispersion liquid and automatic adjustment of the feed rate of dry samples round off the ease of use.

Users can choose from three powerful dispersion units for the Litesizer DIA 500, which can be exchanged quickly and easily depending on requirements. In the liquid flow dispersion unit, the particles are added to a solvent. They disperse in it and are then carried with the solvent into the measuring cell to be measured with the camera. In the dry-jet option, the particles are conveyed into the measuring cell using compressed air, so that even coherent particles split up and can be measured individually. The free-fall dispersing unit relies on gravity – the particles fall into the measuring cell.